Software

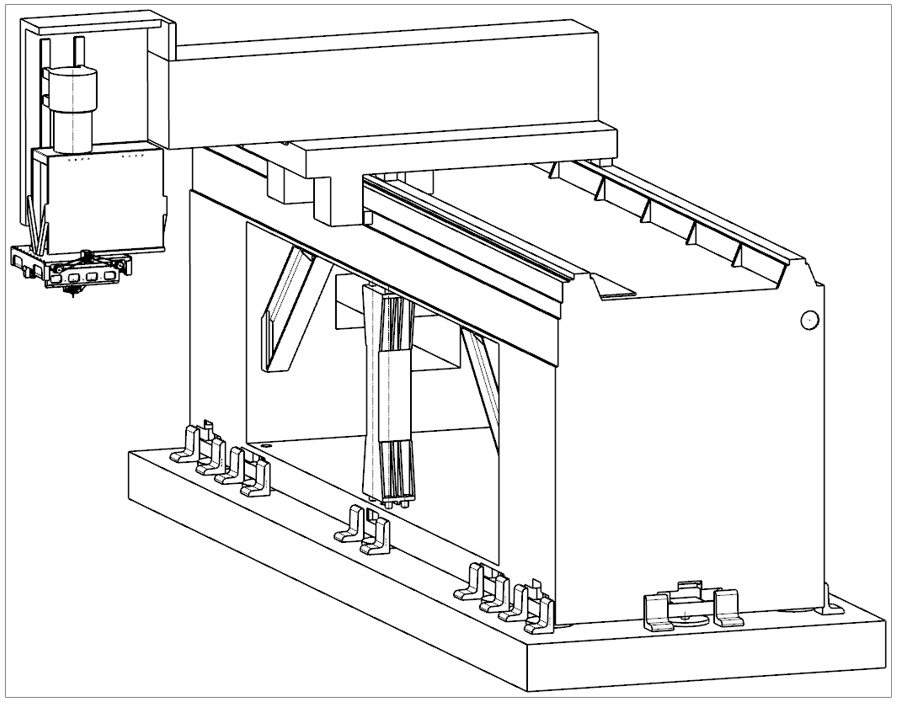

Flexibility

A powerful integrated PLC programming environment and a user friendly and easy to use HMI development application.

Precision

OPENcontrol provides advanced trajectory and dynamics control algorithms.

Key features

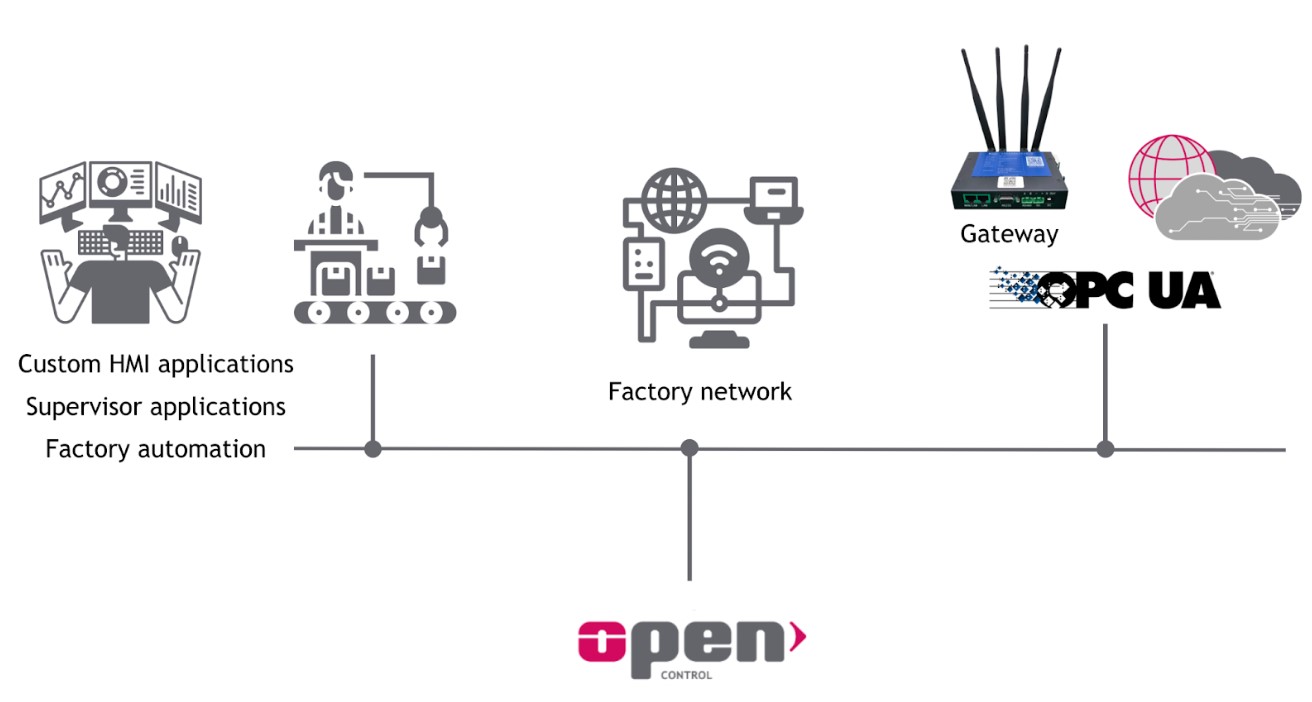

- Industry 4.0 ready

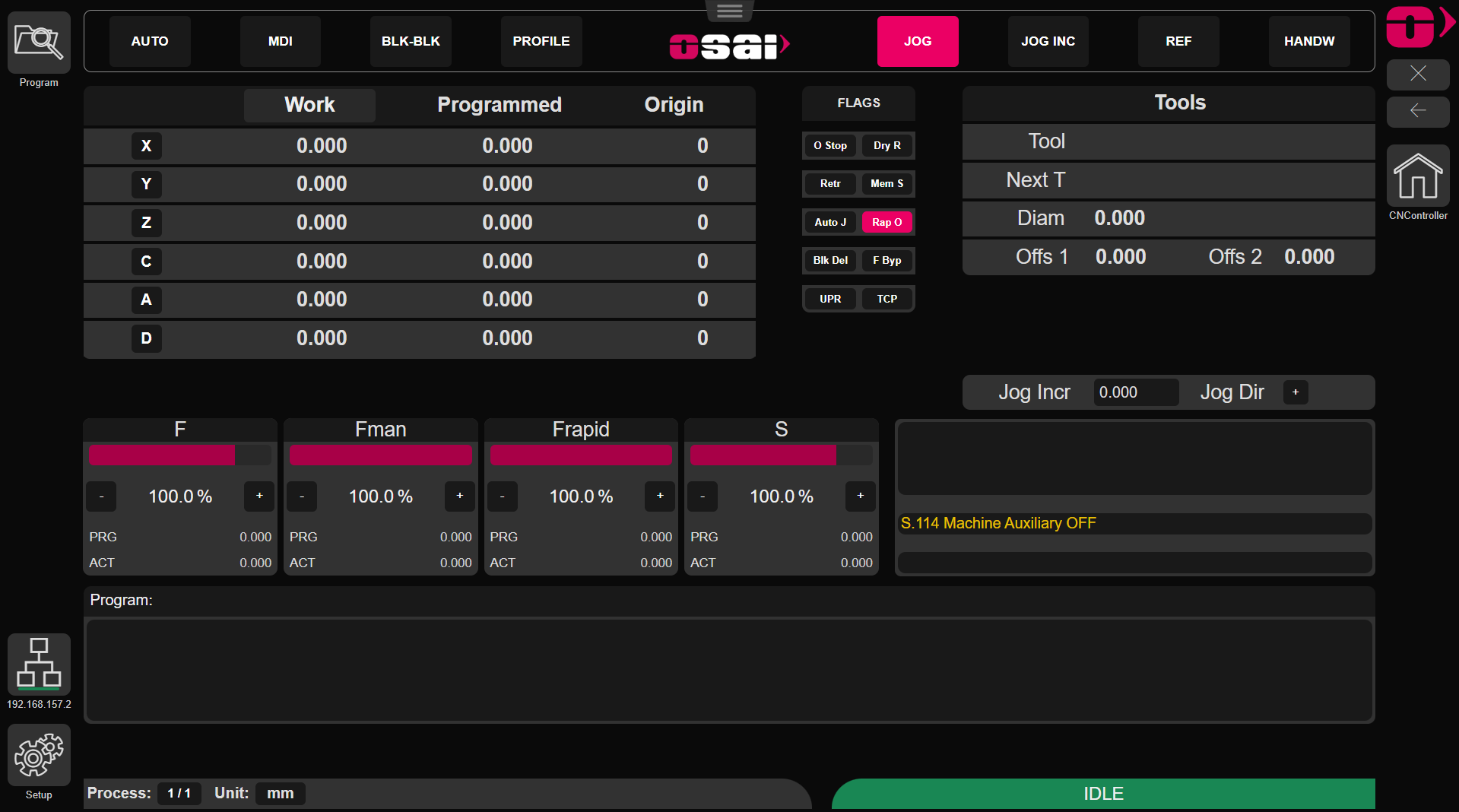

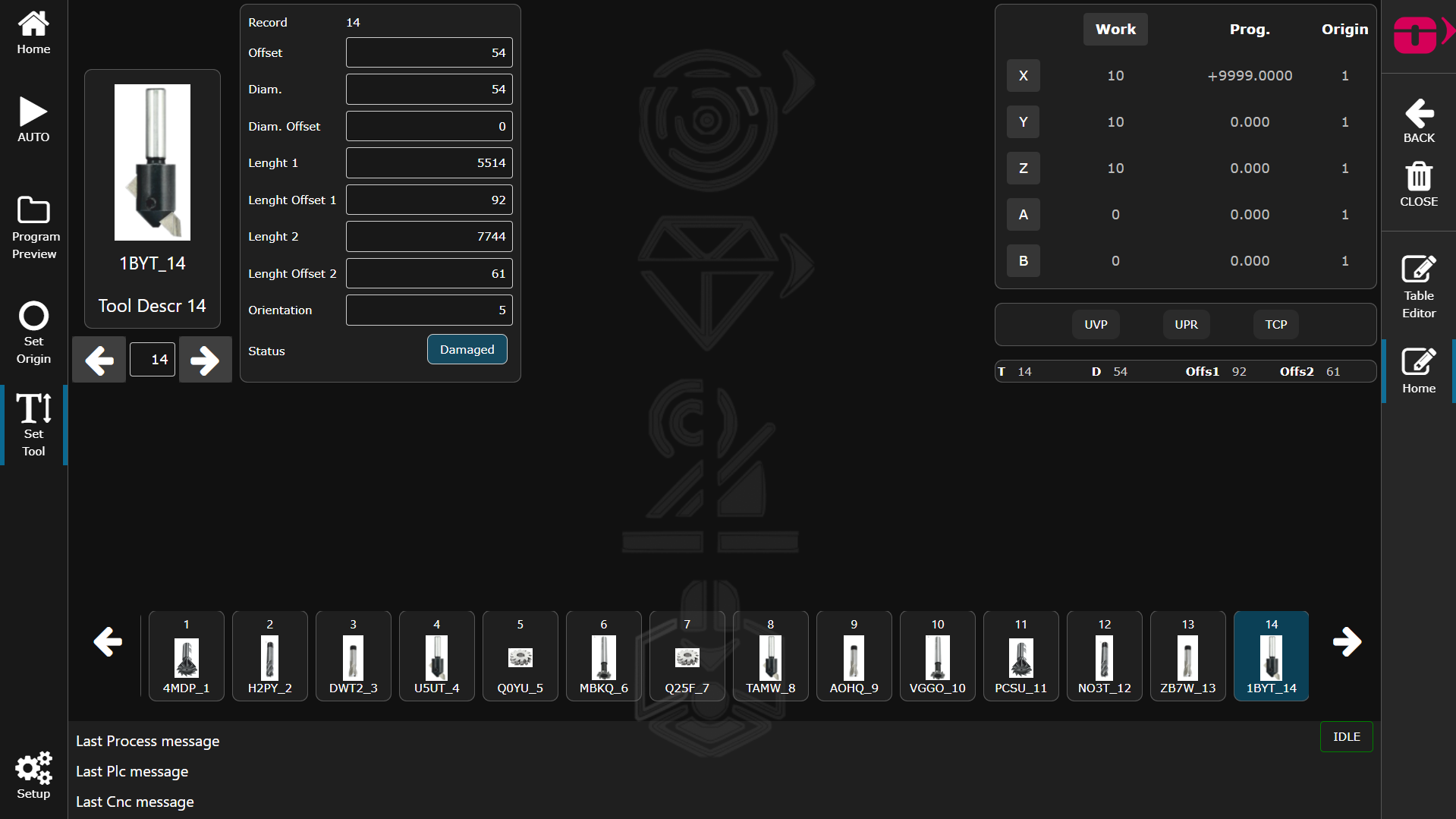

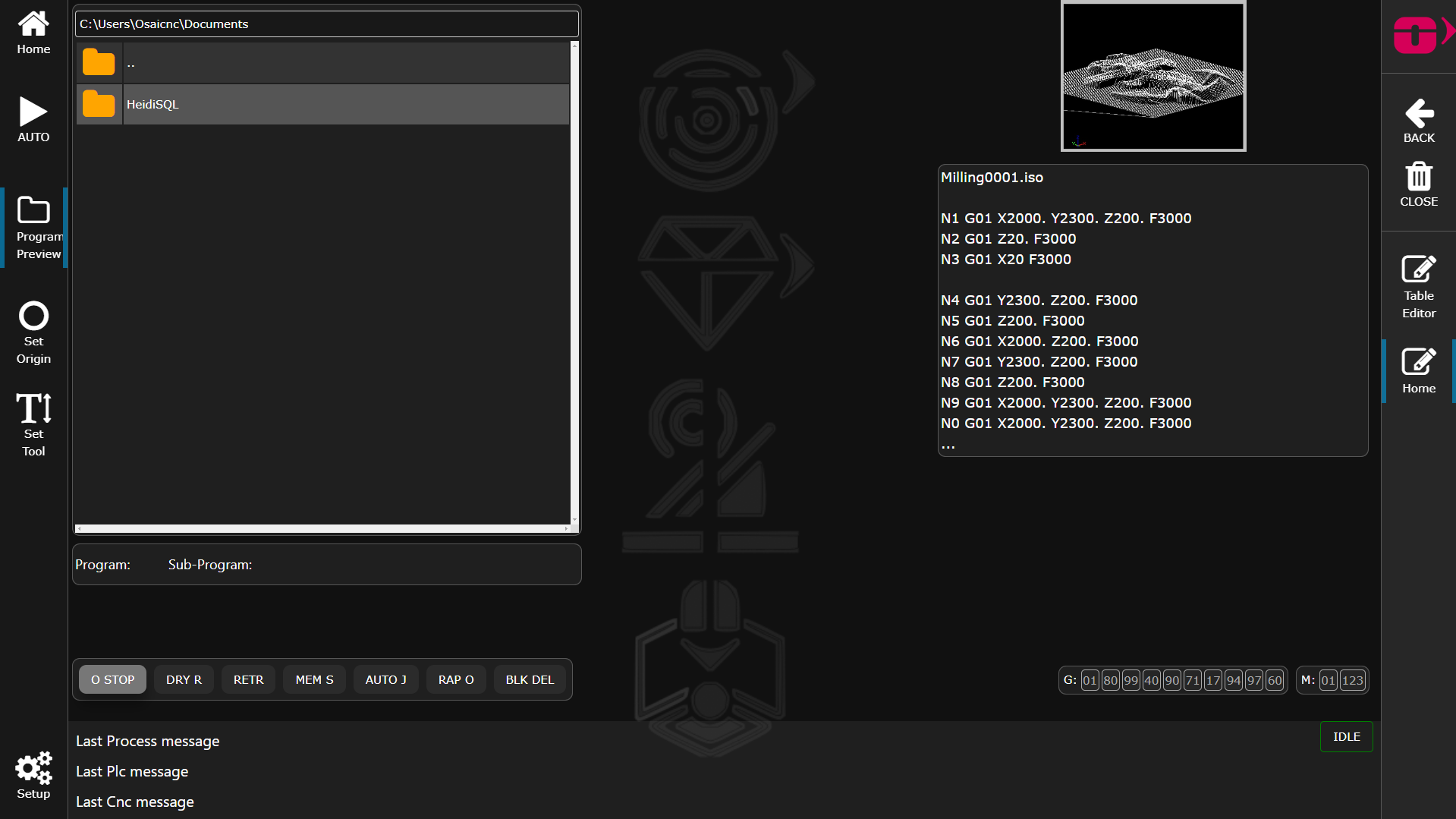

- Fully customizable HMI

- +1000 PLC functions including axes interpolation

- Digital Twin

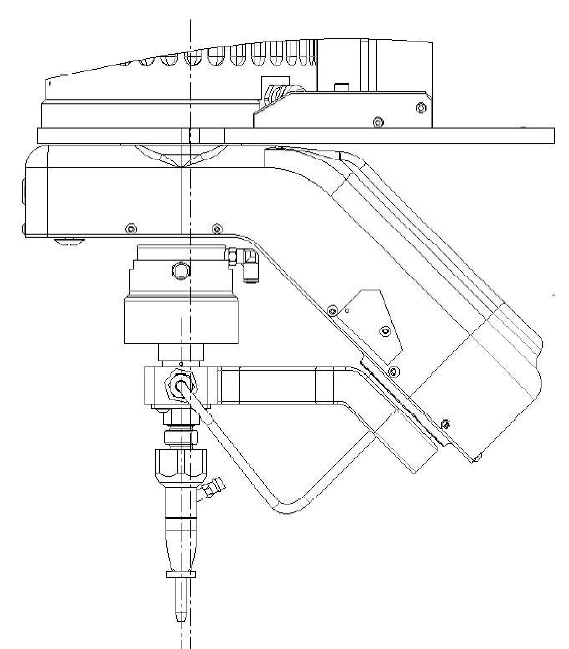

- Cutting-edge Tool Center Point (TCP) algorithms

- Custom kinematics & virtualizations

- High Speed Cutting algorithms

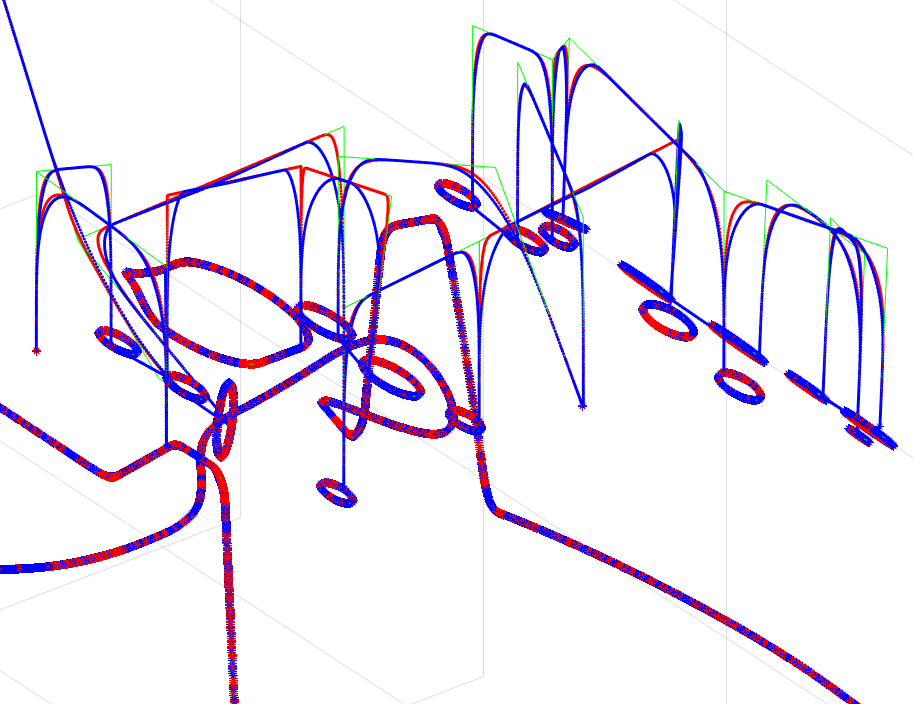

- Splines Interpolation

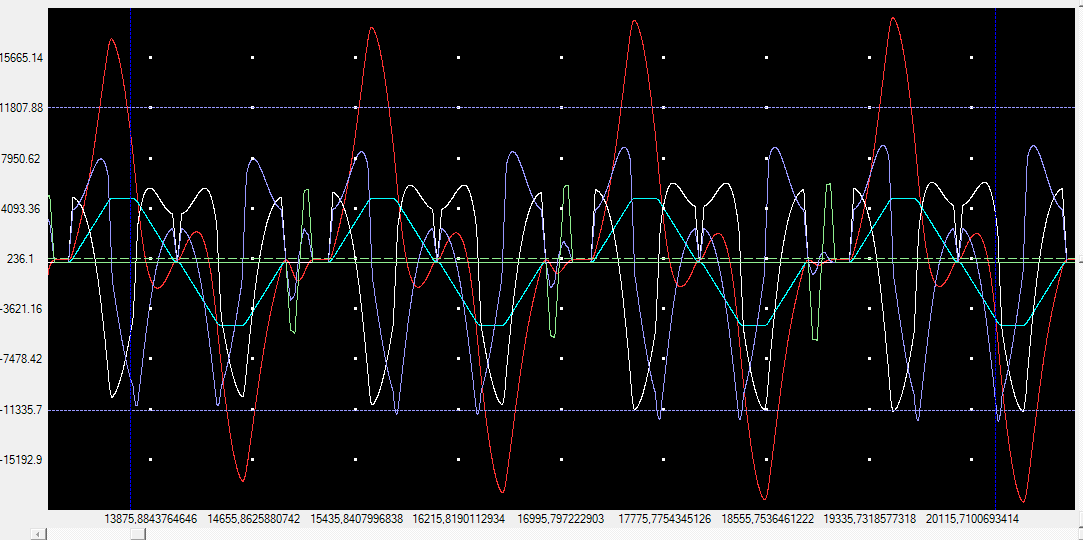

- Predictive Dynamics

- Multi-axis Electronic CAM

- Volumetric Compensation

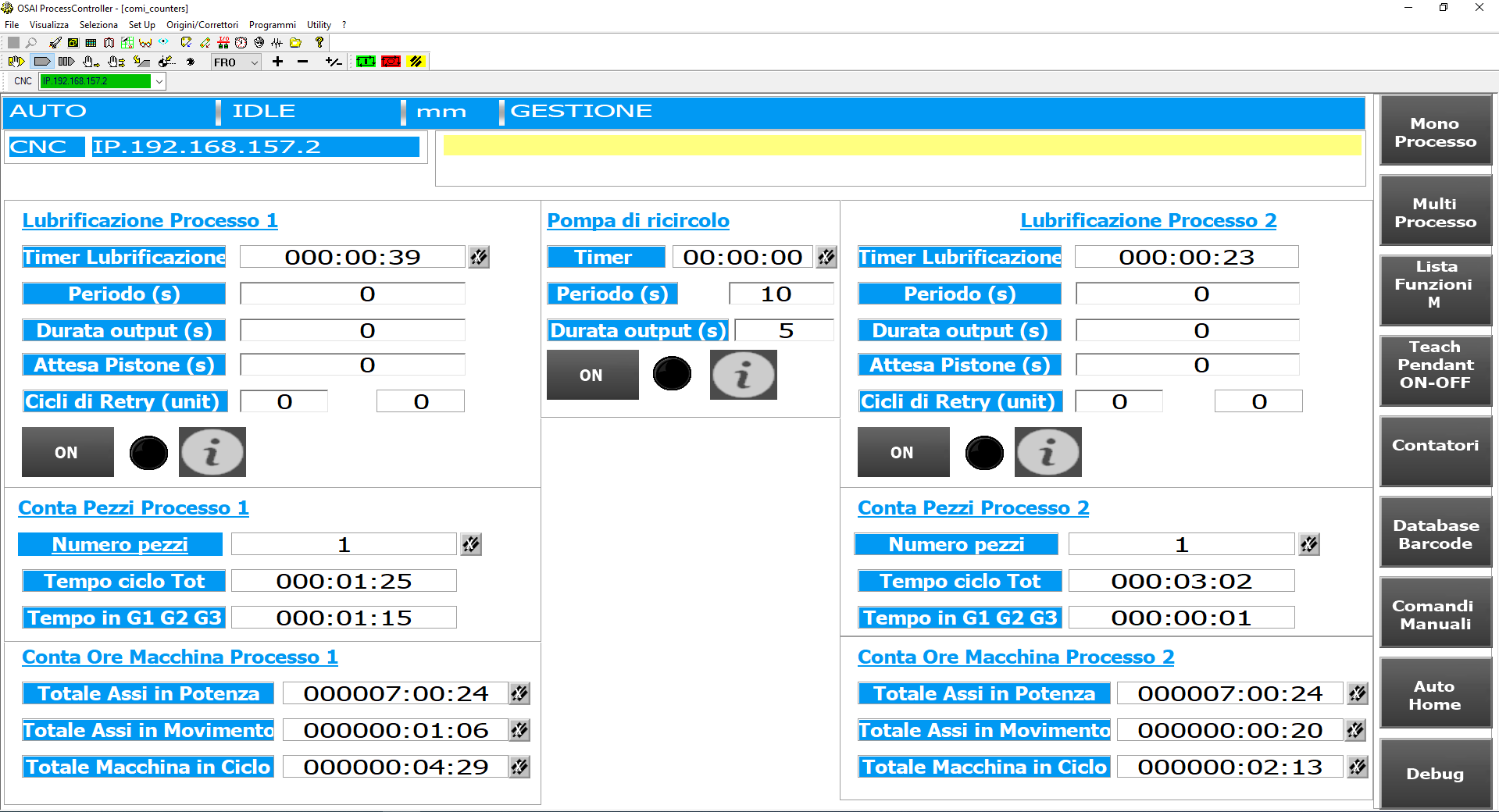

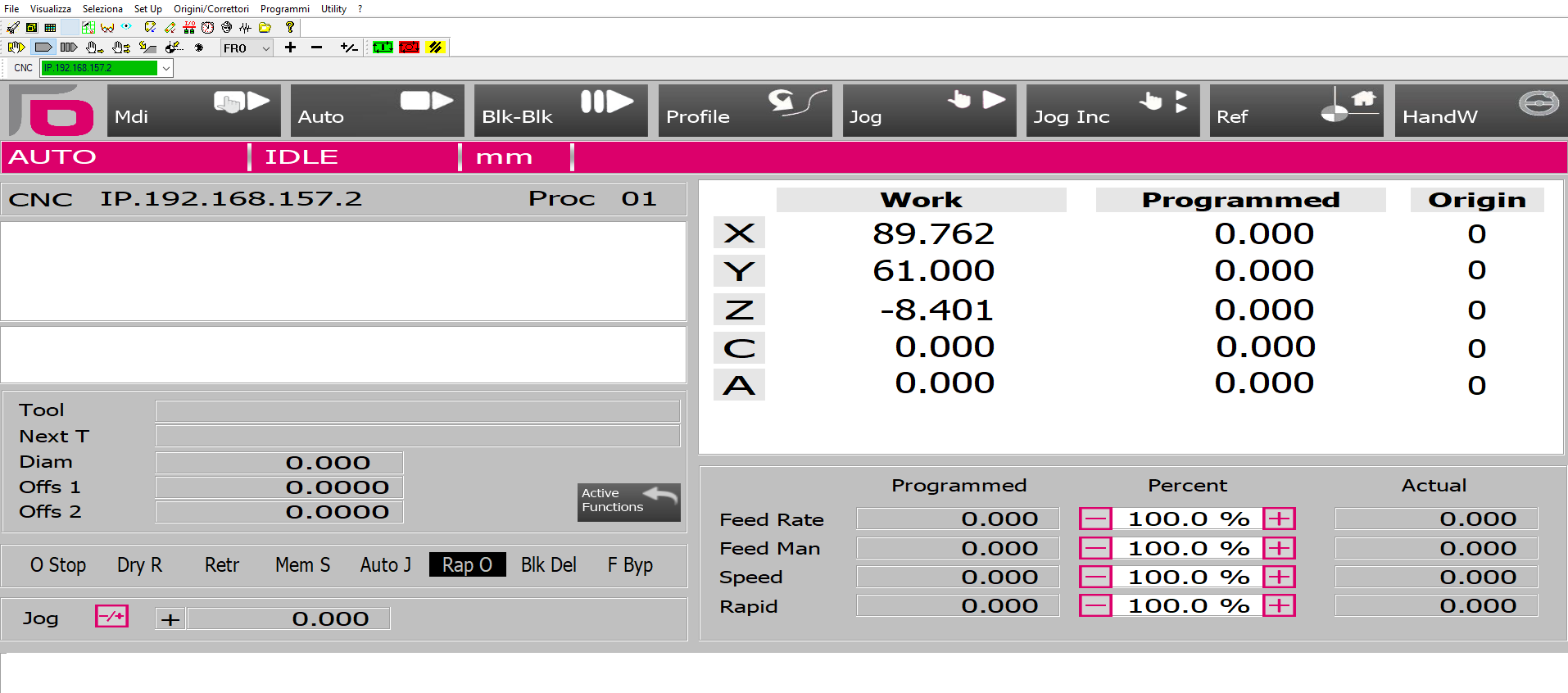

Fully customizable HMI

The Layout Builder tool allows to configure custom video panels in a few clicks and without any software developing knowledge. Moreover, for the most experienced users, OSAIcnc provides the Process Controller Engine, a tool which allows to integrate third party applications and develop even more complex interfaces

Predictive dynamics

Advanced Dynamics Control algorithms to push machine performance to the maximum limits set on the axes.

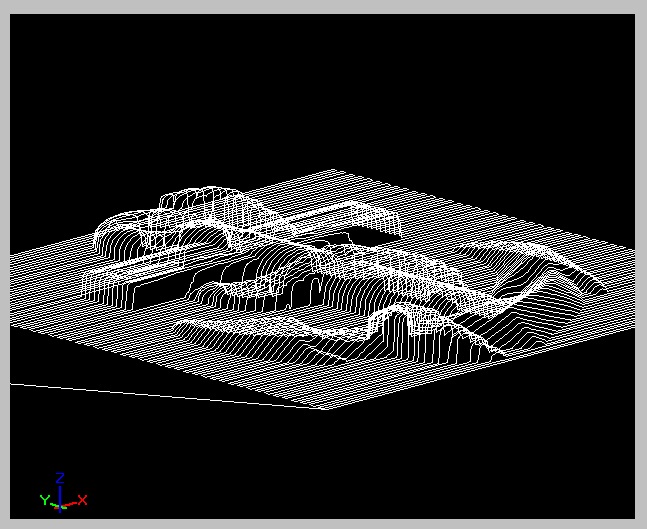

High speed cutting

Innovative Splines Interpolation algorithms, which can be programmed in combination with OSAIcnc PREDICTIVE DYNAMICS, achieving cutting-edge results in terms of cycle time and accuracy.

Integrated PLC

- IEC 61131-3 development environment

- Multi-tasking real-time execution

- Up to 250 tasks, 10 priority levels

- Cyclic and event-driven tasks

- +1000 functions available including axes interpolation

- Custom and C++ integrated functions

- On-line debugging (tracing, breakpoint etc.)

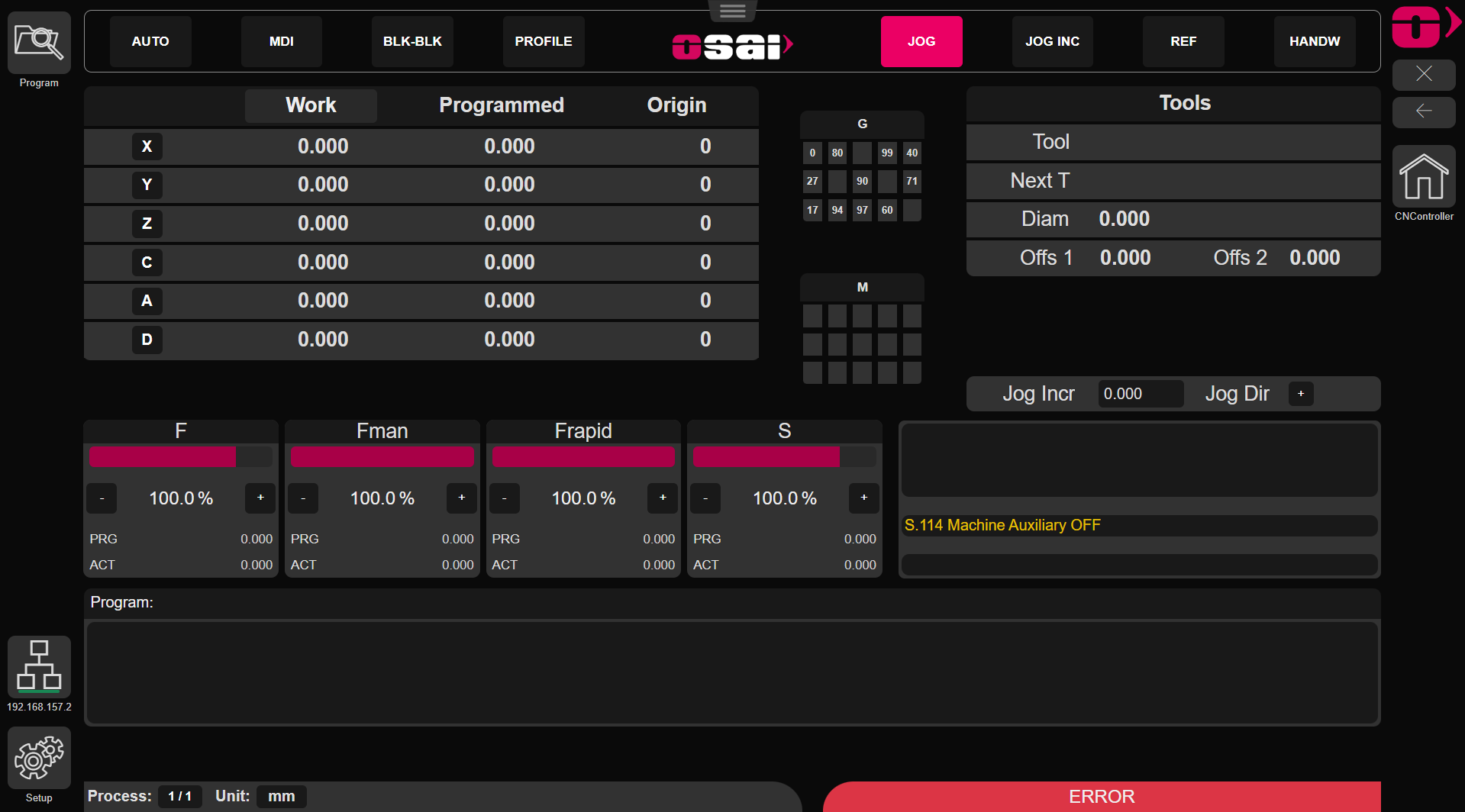

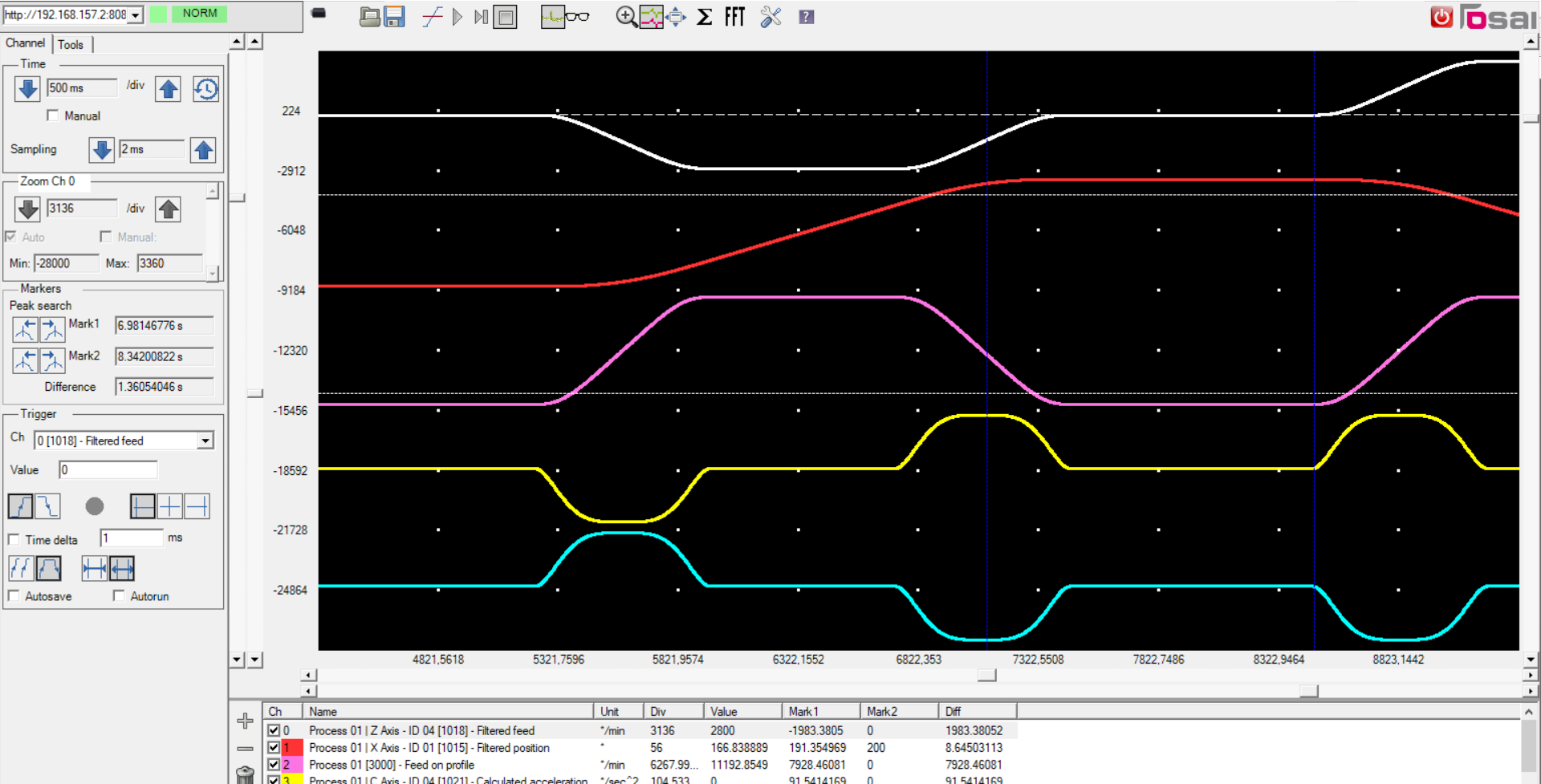

Diagnostics

With the O-SCOPE, the Cycle Time Evaluation tool and several exhaustive DEBUG HMI Pages OSAIcnc provides an all-around system to monitor and debug its customers’ applications.